Global Leader In Metal Casting Products & Custom Manufacturing

Your best one-stop source for ingot molds, sow molds, pig molds, melting pots and furnaces. All projects delivered on time and on budget. Free consultation by world-class experts.

Dynaform Technologies specializes in the design and production of Cast Iron and Ductile Iron Ingot Molds, Sow Molds, Pig Molds, Slag Molds and Slag Pots. All our sow molds are known for their excellent construction and our attention to detail.

If your business involves smelting, recycling, refining and/or metal alloy production, Dynaform’s standard and custom sow molds can help you get the job done in an efficient and profitable manner.

Our customized sow molds are produced in many different sizes and shapes depending upon your need. The sow molds are typically made of cast iron, ductile iron or steel and are regularly used in the casting of aluminum, zinc, kirksite, lead, Copper and Galvalume.

Beyond its specific required function, we consider many additional factors that can determine the optimal use of your sow molds. Based on our vast professional expertise, we know that factors such as your furnace size, fork-lift, and crane capacity need to be addressed carefully before deciding on a sow mold design that fits seamlessly into your operation.

Take Advantage of Our Large Inventory of Sow Molds!

We always maintain a large inventory of finished sow molds and melting pots. If the standard sow mold or melting pot you need is not in stock, we can manufacture and ship it to you within just a few weeks.

That’s the Dynaform Service!

Since 1938, the Pottstown division of Dynaform Technologies has been a leading source of air cooled and water cooled ingot molds, sow molds, pig molds, slag pots and slag molds for secondary smelters worldwide.

Our expertise, outstanding production quality, and attention to detail are second to none. That’s why Dynaform molds are well known for their durability and excellent design among Secondary Smelters around the world. As a result, their extended lifecycles will boost your production and performance, saving you both time and money.

Our sow molds can be cast in a broad range of shapes and sizes and from a variety of alloys, including (but not limited to):

Dynaform - Your Best Choice For Custom Sow Mold Designs

If you already have your own custom design, that’s great! If not, one of our experienced and skilled designers will be happy to assist you. Never compromise on quality and reliability. Take advantage of our technical knowledge which is derived from years of practical experience.

You present us with your specific requirements

We create an initial technical drawing

You approve or suggest changes to the technical drawing

We build a suitable pattern which meets your design criteria

We cast, machine and assemble your mold (if required)

From the initial consultation to our finished mold, Dynaform Technologies’ design and manufacturing expertise streamlines your project, saving you time and money.

Samples of Recent Sow Mold Projects

Rely On Our Professional Excellence For All Your Sow Molds & Ingot Mold Needs

Brand New 18″ Conical Slag Pot

We now produce an 18″ conical slag pot.

Ductile Iron Sow Mold

Made from Ductile Iron, this 5,000 cubic inch Sow Mold is suitable for the casting of Aluminum, Tin, Zinc or Lead. The design and dimensions can be customized to your specific requirements.

1500-F Sow Mold

This 10,500 cubic inch, Ductile Iron Sow Mold weighs approximately 2,000 lbs. It will hold approximately 2,500 lbs. of zinc, 4,200 lbs. of lead or 900 lbs. of aluminum.

ZAMAC Sow Mold

This is our 1,600 lb. Ductile Iron ZAMAC Mold.

Ductile Iron Blast Slag Molds

These Ductile Iron Slag Molds have a capacity of approximately 12,000 cubic inches.

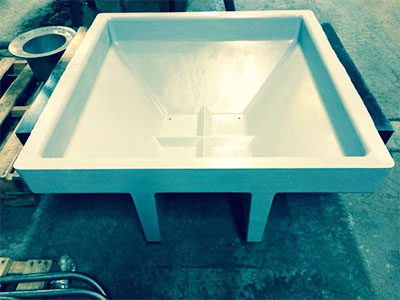

Ductile Iron Slag Mold

New pattern for an 8,000 cubic inch capacity ductile iron slag mold. 2-1/4” thick wall with outside dimensions of 45-1/2” x 45-1/2” x 21”. Mold will weigh approximately 3,000 pounds empty.

Let's Get Started!

At Dynaformtech we work closely with each one of our clients from the initial consultation to the final delivery. As a reputable company, our clients' satisfaction is our top priority!

We create custom patterns, jobbing, type casting and machining, at every possible quantity and weight. We stock a large inventory of finished molds, melting and holding pots that are ready to ship in as little as a few days.

Everything we produce is proudly made in the US! Contact us now and see how we can help you with your Casting or Machining project.